It looks like nothing was found at this location. Maybe try one of the links below or a search?

-

Outdoor Rated Summation, Marshalling or Substation Protective Panels with sun shields. NEMA 3R, 4 and 4x designs.

-

Dual Switchboards - these designs include front and rear panels with one side hinged for access that allow for side and rear mounting of equipment.

-

“Substation In a Box”

Protective Relay Panels with Battery and Charger

-

Vertical Dual Protective Relay Panels with Metering

-

Walk In Enclosures – custom built to specifications. Duplex Switchboards front and rear mounting with top, bottom or end access with or without doors.

-

Summation Panels – indoor or outdoor rated enclosures for current summing requirements

-

Switchgear Enclosure Manufacturing and Assembly – built to your design specifications, partial or complete assembly.

-

Mine and Quarry Skid Fabrication and Refurbishing

-

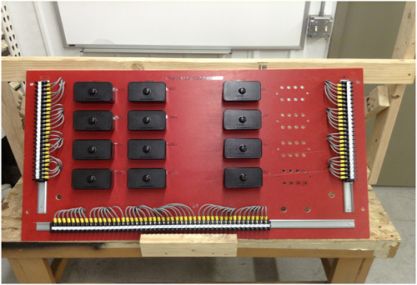

Custom Operator Consoles

for Powerplant Applciations

Control and Relay Panel Fabrication, Custom Fabrication and Engineering Design, Custom Enclosures

Copyright Krage Manufacturing LLC © 2015, All Rights Reserved - Designed